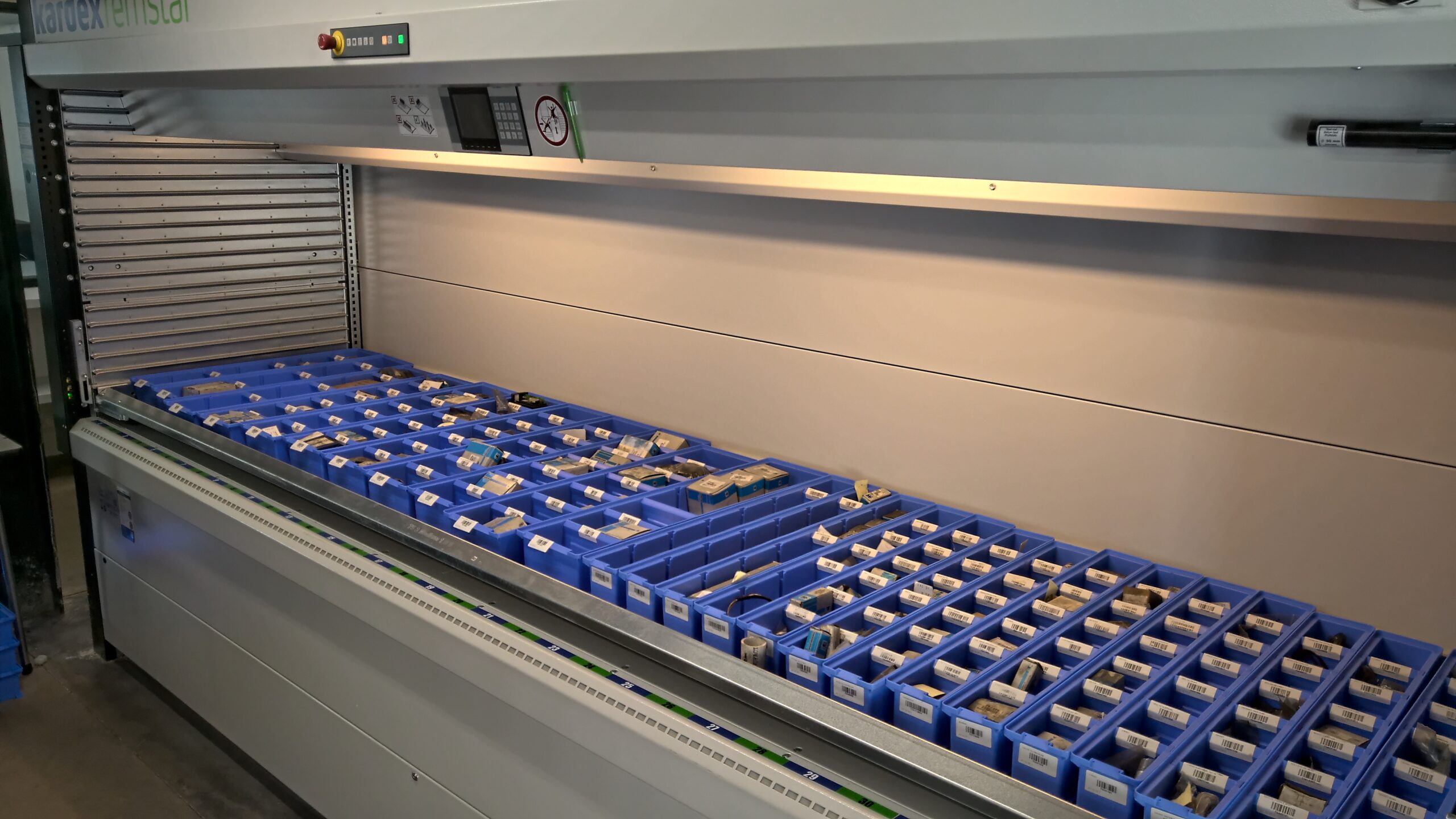

Filling the vertical lift warehouse at Westcool “With the services of eff-fill you know that everything will be okay”

Westcool in Hooglede-Gits is a distributor and maintenance centre for refrigeration units for delivery vans, trucks and trailers. The company has nine employees. When the company moved its warehouse from an old, non-automated carrousel rack system to a fully automatic lift system, it called in eff-fill.

Project details

date 2020-11

- 1 x Kardex Shuttle XP 500 controlled by Carfac M

- 53 trays filled (3650 x 864)

- 1458 different parts

- Vertical space used: 9050 mm

Manager Jan Ledaine: “We have known Jan for a long time. During our search for a new warehouse solution, we even went to look at a certain system together so that he could give us some tips. It was the most natural thing for us to involve him in the transformation of our warehouse.

Working from an inventory of all parts, Jan made the calculation for the most efficient warehouse filling with his eff-fill software. Based on that information, we purchased the appropriate containers. Thanks to the good preparation ‒ Jan even took care of the pre-printed stickers for the trays ‒ we were able to move all the parts in one day. It was really a relief that everything fit perfectly. The system works impeccably.

I have often recommended Jan’s services to colleagues because I’m genuinely very satisfied with his work. When you work with Jan, you can be sure that everything will be okay. He takes a very orderly and structured approach, knows exactly what he’s doing and has a lot of experience. I also consider the fact that he works with his own software to be a real added value. He knows it inside and out.”

Project details

Datum 2020-11

1 x Kardex Shuttle XP 500 controlled by Carfac M53 trays filled (3650 x 864)

1458 different parts

Vertical space used: 9050 mm