Vergauwe K&P

Vergauwe K&P in Nieuwpoort is a 3rd generation family business that sells and repairs agricultural and horticultural machines, but also carries out soil and agricultural work itself. After installing a brand-new warehouse lift, they called on eff-fill to do the layout.

Project details

date 2020-02

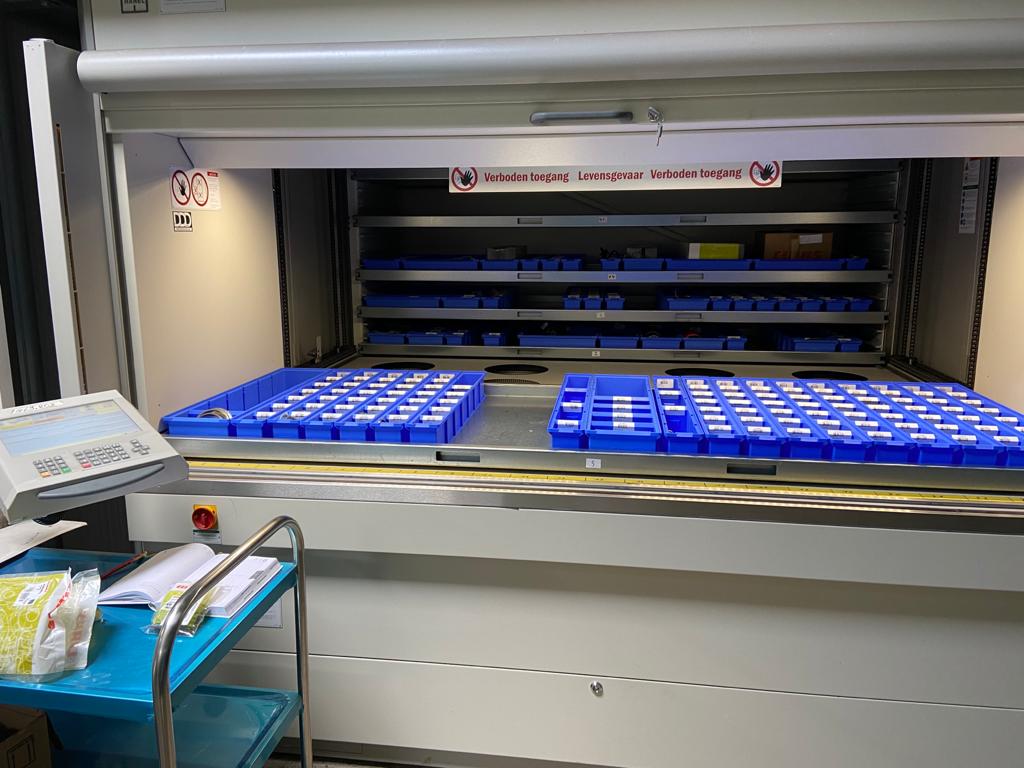

- 1 x Hänel Leanlift® controlled by CarfacM

- 32 drawers filled (2,460 x 825)

- 1,482 different part

“Jan once organised the stock for us and he does good advertising for his warehouse services, so it didn’t take long to make the choice to call on him to fill in our new warehouse lift”, says Ann Stroo.

“We had a specific requirement to combine different groups of parts per drawer so that we could use fewer drawers and still keep certain parts together. That took a lot of puzzling, but Jan started working on it and using his software program eff-fill, he effectively found a solution. But it didn’t stop there: you not only get an overview and a schedule for proper filling, but also a lot of advice. Jan was there when we did the inventory beforehand and also for the final move. He explained everything clearly, step by step. If we had done everything ourselves, it not only would have taken much longer, but it would have been less efficient. We would certainly recommend that other companies use Jan’s experience and knowledge.”

Project details

Datum 2020-02

1 x Hänel Leanlift® controlled by CarfacM32 drawers filled (2,460 x 825)

1,482 different part